Infrared thermography scanning, electrical infrared inspection, infrared thermography services, infrared thermography building inspection

Our Technology

WHAT IS INFRARED THERMOGRAPHIC SCANNING? Infrared thermography scanning, electrical infrared inspection

Infrared thermography is an NDT (Non-Destructive test) examination without direct physical contact with the object. Thermographic cameras usually detect radiation in the long-infrared range of the electromagnetic spectrum and produce images of that radiation, called thermograms. Since infrared radiation is emitted by all objects with a temperature above absolute zero according to the black body radiation law, thermography makes it possible to see one's environment with or without visible illumination.

The quantitative thermography method is commonly used for the inspection. Quantitative thermography is the art and science of detecting, displaying, and recording the thermal patterns and temperatures across the surface of an object. The person who performs infrared inspections is called a ‘Thermographer’. The equipment used for infrared scanning is called a ‘thermal imager’. The thermal imager is a camera-like device capable of detecting, displaying, and recording thermal patterns across the surface of an object. Thermal imagers convert infrared energy to visible light images.

The amount of radiation emitted by an object increases with temperature; therefore, thermography allows one to see variations in temperature. The uses of thermography scanning are : -

- As a preventive / predictive maintenance

- Condition assessment

- Condition monitoring

- Quality assurance

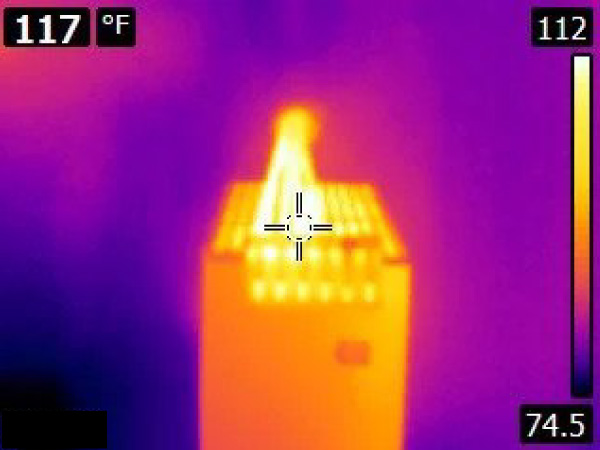

In a thermographic image:

- A "hotspot" would be an area that appears as a warmer colour, indicating a higher temperature.

- A "cold spot" would be an area that appears as a cooler colour, indicating a lower temperature.

HOW IS IT MEASURED? Infrared thermography scanning confirm machinery is running normally and to detect abnormal heat patterns within a machine. electrical infrared inspection can recognize stressed elements of your electrical installation before they break down or cause a fire. electrical infrared inspection and Infrared thermography scanning an inexpensive way to inspect an electrical system both visually.

Thermal imaging cameras are designed to provide accurate thermal recordings based on heat signatures. They translate thermal radiation, which is normally not visible to the naked eye, into visual images with different colors indicating heat levels. For example, dark red stands for abnormally high temperatures, whereas blue shades indicate cooler temperatures. The thermal imaging results are fairly simple to read and anyone trained to use these devices can identify normal from abnormal temperatures.